What are valves?

The basic valve is used to permit or restrain the flow of fluid and/or adjust the pressure in a system. A complete control valve is made of the valve itself, an actuator, and, if necessary, a valve control device. The actuator is what provides the required force to cause the closing part of the valve to move. Valve control devices keep the valves in the proper operating conditions; they can ensure appropriate position, interpret signals, and manipulate responses.

When implementing a valve into a process, one must consider the possible adverse occurrences in the system. This can include noise due to the movement of the valve, which can ultimately produce shock waves and damage the construction of the system. Cavitation and flashing, which involve the rapid expansion and collapse of vapor bubbles inside the pipe, can also damage the system and may corrode the valve material and reduce the fluid flow.

There are four general types of valves.

- Electronic, or electrical valves. The movement of the ball or flap that controls flow is controlled electronically through circuits or digitally. These types of valves have very precise control but can also be very expensive.

- Non-Return valves. These valves allow flow in only one direction, and are common in various industries. When pressure in the opposite direction is applied, the valve closes.

- Electromechanical valves. These valves have electro magnets controlling whether the valve is open or closed. These valves can only be fully open or fully closed.

- Mechanical Valves. These valves use mechanical energy in the process of opening and closing the actual valve. Larger valves can be opened and closed using mechanical processes such as levers and pulleys, whereas smaller mechanical valves can be opened or closed via a turning wheel or pulling a level by hand.

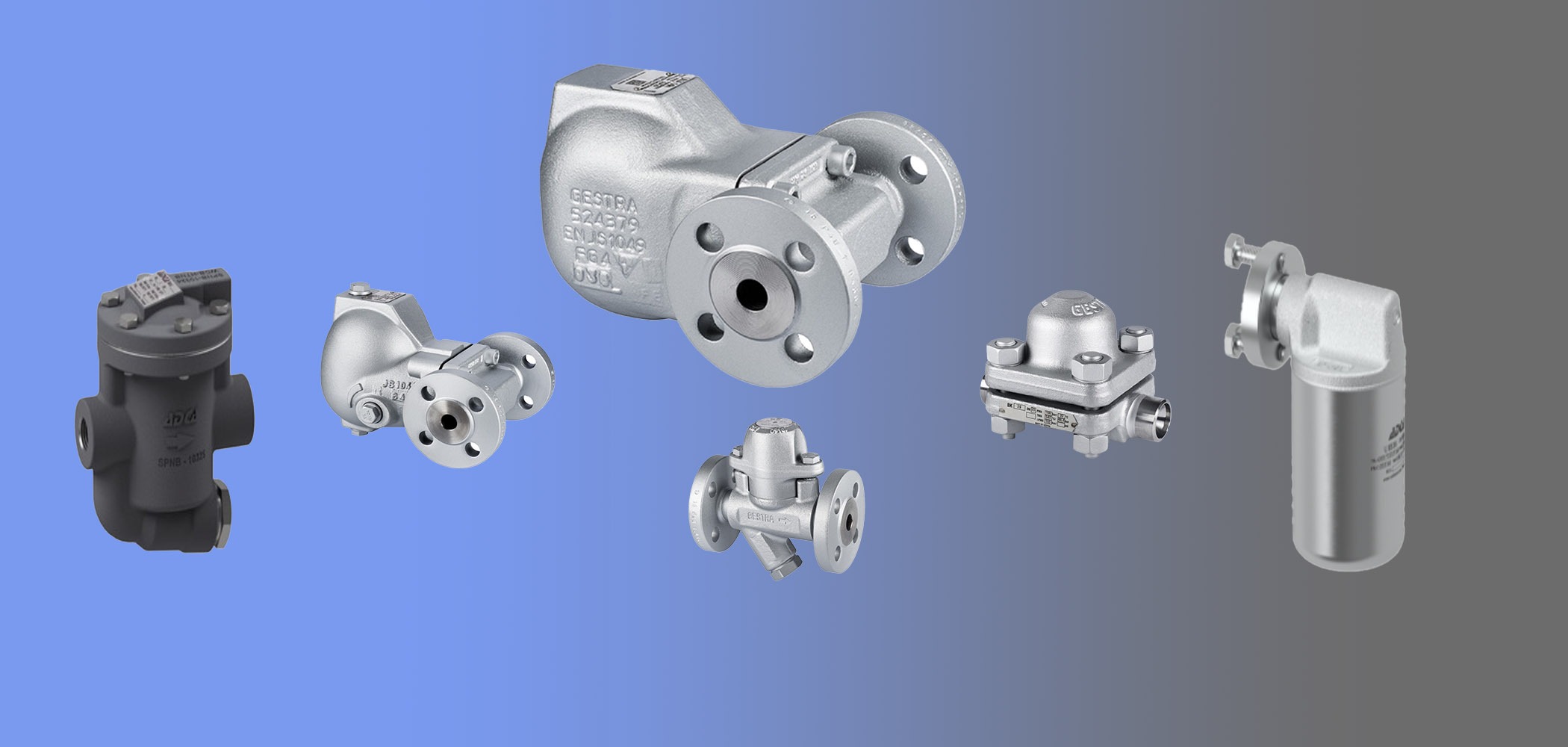

Type of Valves

There is a vast abundance of valve types available for implementation into systems. The valves most commonly used in processes are ball valves, butterfly valves, globe valves, and plug valves. A summary of these four valve types and their relevant applications is in the table below.

| Valve Type | Application | Other information |

|---|---|---|

| Ball | Flow is on or off | Easy to clean |

| Butterfly | Good flow control at high capacities | Economical |

| Globe | Good flow control | Difficult to clean |

| Plug | Extreme on/off situations | More rugged, costly than ball valve |

Ball Valves

A ball valve is a valve with a spherical disc, the part of the valve which controls the flow through it. The sphere has a hole, or port, through the middle so that when the port is in line with both ends of the valve, flow will occur. When the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked. There are four types of ball valves.

A full port ball valve has an over sized ball so that the hole in the ball is the same size as the pipeline resulting in lower friction loss. Flow is unrestricted, but the valve is larger. This is not required for general industrial applications as all types of valves used in industry like gate valves, plug valves, butterfly valves, etc have restrictions across the flow and does not permit full flow. This leads to excessive costs for full bore ball valves and is generally an unnecessary cost.

Butterfly Valves

Butterfly valves consist of a disc attached to a shaft with bearings used to facilitate rotation. The characteristics of the flow can be controlled by changing the design of the disk being used. For example, there are designs that can be used in order to reduce the noise caused by a fluid as it flows through. Butterfly valves are good for situations with straight flow and where a small pressure drop is desired. There are also high performance butterfly valves. They have the added benefit of reduced torque issues, tight shutoff, and excellent throttling. It is necessary to consider the torque that will act on the valve. It will have water moving on both sides and when being used to throttle the flow through the valve it becomes a big factor. These valves are good in situations with high desired pressure drops.They are desirable due to their small size, which makes them a low cost control instrument. Some kind of seal is necessary in order for the valve to provide a leak free seal. A common example would be the air intake on older model automobiles.

Globe Valves

A globe valve is a type of valve used for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body. The valve can have a stem or a cage, similar to ball valves, that moves the plug into and out of the globe. The fluid’s flow characteristics can be controlled by the design of the plug being used in the valve. A seal is used to stop leakage through the valve. Globe valves are designed to be easily maintained. They usually have a top that can be easily removed, exposing the plug and seal. Globe valves are good for on, off, and accurate throttling purposes but especially for situations when noise and caviatation are factors. A common example would be the valves that control the hot and cold water for a kitchen or bathroom sink.

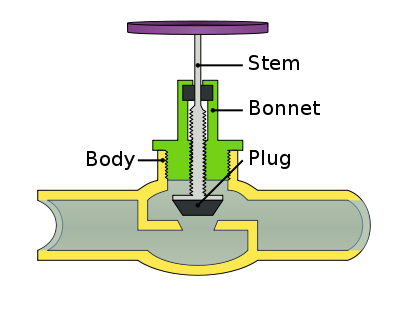

Plug Valves

Plug valves are valves with cylindrical or conically-tapered “plugs” which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug, so that fluid can flow through the plug when the valve is open. Plug valves are simple and often economical. There are two types of plug valves. One has a port through a cylindrical plug that is perpendicular to the pipe and rotates to allow the fluid to proceed through the valve if in an open configuration. In the closed configuration, the cylinder rotates about its axis so that its port is no longer open to the flow of fluid. An advantage of these types of valves is that they are excellent for quick shutoff. The high friction resulting from the design, however, limits their use for accurate modulating/throttling. Schematics of this type of plug valve are below.

Pressure Relief Valves

Pressure relief valves are used as a safety device to protect equipment from over-pressure occurrences in any fluid process. Loss of heating and cooling, mechanical failure of valves, and poor draining and venting are some of the common causes of overpressure. The relieving system depends on the process at hand; pressure relief valves either bypass a fluid to an auxiliary passage or open a port to relieve the pressure to atmosphere. Some areas of common usage include reaction vessels and storage tanks. In the Petroleum Refining Industry, for example, the Fluidized Catalytic Cracker (FCC) reactor has several pressure relief valves to follow saftey codes and procedures on such a high pressure/high temperature process. Each of the pressure relief valves have different levels of pressure ratings to release different amounts of material to atmosphere in order to minimize environmental impact.

Other Valves

In addition to the four main types of control valves, there are numerous other valves that may be necessary to manipulate fluid flow in a certain system. Some valves important to chemical engineering processes are stated below with a brief description of their design and application.

- Angle valves include inlet and outlet ports that are oriented at a 90 degree angle. The fluid leaves at right angles to the direction in which it enters the valve.

- Bleed valves vent signal line pressure to atmosphere before removal of an instrument or to assist in calibration of control devices. Common bleed valves include ball and plug bleed valves.

- Check valves are one way valves. Check valves only allow fluid in one way and out the other. They are often placed on individual fluid streams when mixing fluids so as to prevent the mixture from flowing back into the original streams. Also, the speed with which the valve closes is significant to prevent reverse-flow velocity. There are different types of check valves which include lift check, swing check, tilting disk and diaphragm.

- Lift check valves are quick closing. This valve should only be used for low viscosity fluids because they can be slowed by viscous fluids.

- Swing check valve has a disc like closing method from a hinge which may or may not be spring loaded.

- Tilting disk check valve is spring loaded for quick response. These are often more expensive and harder to fix when broken.

- Diaphragm valves have excellent shut-off characteristics and are used when there is particulate matter in the fluids. Not a good choice for controlling flow. A diaphragm valve has both a flexible and a rigid section. One advantage is that there are no crevices that affect the flow of the fluid when open. Used mostly in the pharmaceutical and food industry for their ability to be sanitary.

- Piston valves have a closure member shaped like a piston. When the valve opens, no flow is observed until the piston is fully moved from the seat bore, and when the valve closes, the piston removes any solids that might be deposited on the seat. Therefore, piston valves are used with fluids that have solid particles in suspension.

- Gate valves work by raising a gate or barrier out of the way of the flowing fluid. The water spigot outside a house works as a gate valve. Have the positive quality that, when fully open, the fluid flow is totally unobstructed. Two major types of gate valves are used: parallel and wedge gate valves. The wedge gate valve, in which the closure member has a wedge shape, provides the advantage of sealing against low pressure, as well as high pressure, flow. Gate valves have the ability to open very quickly. Advantages of gate valves are that they have a high capacity, have good seals, relatively inexpensive, and don’t have very much resistance to flow. Some disadvantages of gate valves are that they sometimes can have poor control, they can cavitate at lower pressures, and they cannot be used for throttling.

- Needle valves are similar to gate valves; however, they are usually applied to a much smaller orifice. Needle valves are excellent for precise control of fluid flow, typically at low flow rates.

- Flush Bottom valves are usually at the lowest point of a tank or reactor and used to drain out contents. Unique because it leaves no dead space in the valve when it is closed, this eliminates the problem of product buildup within the valve.

- Pinch valves are mainly used in order to regulate the flow of slurries in certain processes and systems. Pinch valves have flexible bodies that can be shut by pinching them. They are often used when it is necessary for the slurry to pass straight through when the valve is not pinched. They are often used for sanitary processes such as medical and pharmaceutical applications. Pinch valves can be controlled mechanically or with fluid pressure.

- Knife valves are used in systems that deal with slurries or powders. They are primarily used for on and off purposes; whether or not the slurry or powder flows or not. A knife gate valve can be used for fibrous material because it can cut through to close the valve.

- Ballcock valves are used in controlling levels in tanks. The valve is connected to a float in the tank using a lever. When the level in the tank rises, the float rises and forces the valve to be shut at the maximum level of the tank allowed. Ballcock valves are used mostly in water tanks and other low-risk areas within a certain process.

- Solenoid valves are used very frequently in industry. The valves have a loop of wire that is wrapped around a metal core. A current is shot through the valve creating a magnetic field, which in turn opens or closes plungers in pipelines controlling flow in that pipe.