What are steam traps?

Steam traps are devices used in steam systems to automatically remove condensate and non-condensable gases, such as air, from the system without letting any steam escape. They are essential components in steam systems as they help to maintain the efficiency and safety of the system by preventing damage caused by water hammer, corrosion, and uneven heating.

Steam traps work by opening and closing in response to changes in temperature, pressure, or density, allowing the condensate to be discharged while keeping the steam in the system. There are several types of steam traps available, including float and thermostatic, thermodynamic, and inverted bucket traps, each with its own specific application and performance characteristics.

Steam traps need to be regularly inspected and maintained to ensure they are functioning properly and prevent costly damage to the system.

What is condensate and mixture in steam?

Let’s first try to understand how this mixture forms:

- Condensate: Condensate forms whenever steam releases its heat energy for any reason.

- Air: Air exists in all steam pipes prior to system start-up when the system is cold. Air can enter the system through boiler water make-up systems and vacuum breakers.

- Non-Condensable gases: Gases other than air such as carbon dioxide exist inside steam systems.

What are type of steam traps?

There are several types of steam traps, each with its own design and operating principles. Here are some of the most common types:

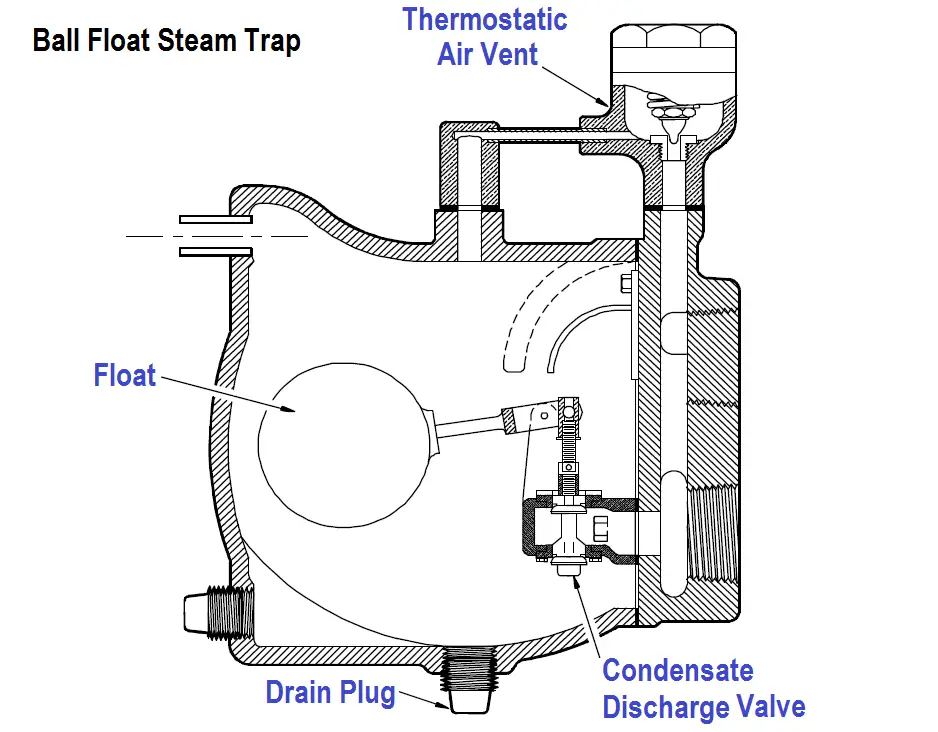

Float and thermostatic (F&T) traps: These traps have a float that rises and falls with the level of condensate. When the float rises, it opens a valve to discharge the condensate. F&T traps also have a thermostatic element that helps to modulate the valve opening based on the temperature of the steam.

Thermodynamic traps: These traps use the principle of the Venturi effect to discharge condensate. The trap has a disc that opens and closes in response to changes in steam velocity and pressure.

Inverted bucket traps: These traps use a bucket that is suspended from a lever inside the trap. When condensate enters the trap, it fills the bucket and causes it to invert, opening a valve to discharge the condensate.

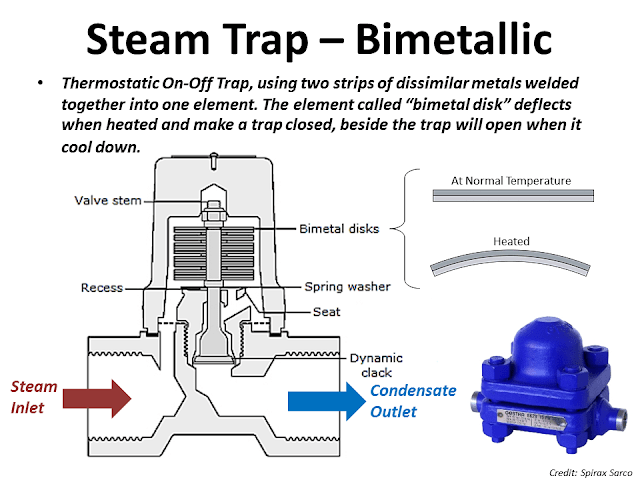

Bimetallic traps: These traps use two strips of metal with different coefficients of thermal expansion. When heated by the steam, the strips bend and close a valve to discharge the condensate.

Thermo-pile traps: These traps use a thermo-pile to generate electricity, which is used to operate a valve to discharge the condensate.

The choice of steam trap will depend on factors such as the application, operating pressure and temperature, and the size and layout of the system.

The Steam Traps can be categorised as

Mechanical Steam Traps:

Float and thermostatic (F&T) traps: These traps have a float that rises and falls with the level of condensate. When the float rises, it opens a valve to discharge the condensate. F&T traps also have a thermostatic element that helps to modulate the valve opening based on the temperature of the steam. When the temperature of the steam decreases, the thermostatic element contracts and closes the valve, preventing steam from escaping.

Inverted bucket traps: These traps use a bucket that is suspended from a lever inside the trap. When condensate enters the trap, it fills the bucket and causes it to invert, opening a valve to discharge the condensate. When steam enters the trap, it heats the bucket and causes it to turn upright, closing the valve to prevent steam from escaping.

Thermostatic traps: These traps use a thermostatic element, such as a bimetallic strip or a wax capsule, to open and close a valve. When the steam temperature rises, the thermostatic element expands and opens the valve, allowing condensate to be discharged. When the steam temperature decreases, the thermostatic element contracts and closes the valve, preventing steam from escaping.

All of these mechanical steam traps work to discharge condensate from a steam system while keeping steam in the system. They operate automatically, without the need for external power or control, making them reliable and efficient components of a steam system. Proper selection, installation, and maintenance of these steam traps are crucial for ensuring the efficient and safe operation of a steam system.