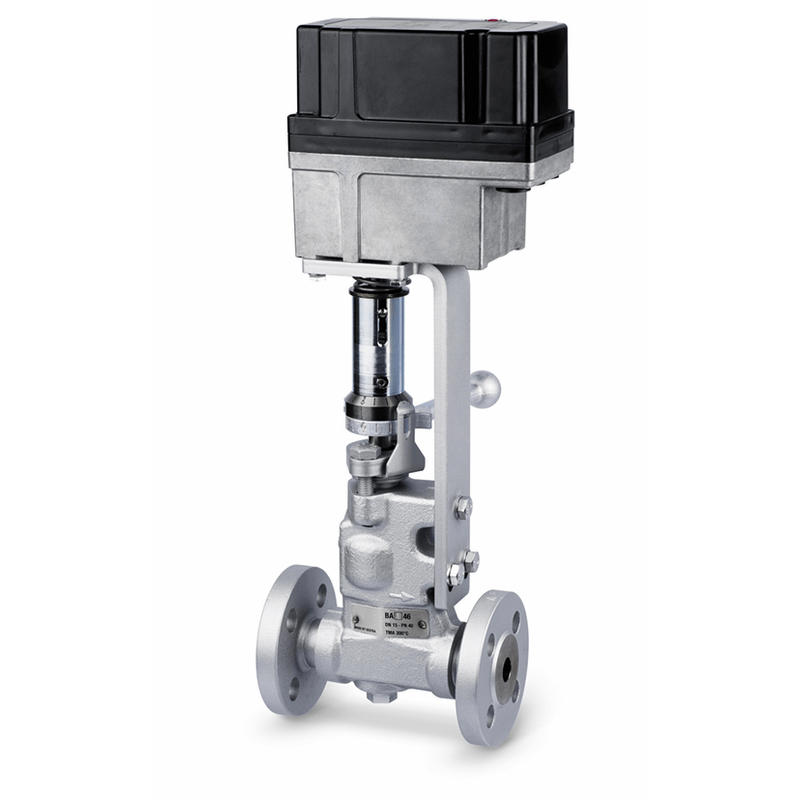

What is a blowdown valve?

A blowdown valve is a type of valve used to rapidly release pressure from a vessel or piping system. It is typically used in steam boilers, where it is used to remove sediment and impurities that accumulate at the bottom of the boiler.

The blowdown valve is usually located at the bottom of the boiler and is connected to a drain pipe that leads to a safe disposal point. When the valve is opened, high-pressure steam and water are quickly released from the boiler, carrying with them any sediment or impurities that have settled at the bottom of the boiler.

Blowdown valves are important safety devices because they help prevent the buildup of pressure in the boiler, which can lead to explosions or other dangerous situations. They are also used to regulate the amount of water and steam in the boiler, which helps to ensure efficient operation and prolong the life of the boiler.

Working principle and types

The working principle of a blowdown valve is relatively simple. It works by providing a pathway for the rapid release of water or steam from a vessel or piping system, typically a boiler.

When the valve is closed, it prevents the flow of water or steam from the system. When it is opened, it allows the water or steam to flow out of the system through a discharge pipe. The valve may have a mechanism to control the rate of flow, or it may be designed for full-bore discharge.

In a steam boiler, blowdown valves are used to remove sediment and impurities that accumulate at the bottom of the boiler. The valve is usually located at the bottom of the boiler, and when opened, it releases high-pressure steam and water, carrying with them any sediment or impurities that have settled at the bottom of the boiler.

Blowdown valves are typically operated manually or by an automated control system that monitors the pressure and temperature of the system and opens the valve as needed to maintain safe operating conditions.

It is a common practice to use two blowdown valves in series. One acts as the seal valve, while the other is the main blowdown valve. Customarily, the seal valve opens first when draining, and closes last. However, to minimize erosion of the valve disk faces and seats, both may open simultaneously and rapidly.

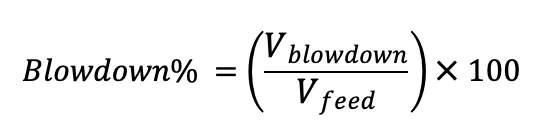

In addition, care should be taken to avoid trapping scale and rust particles within the valve by briefly reopening it, after it has been shut. Especially if there was resistance when closing it initially. One important parameter in the operation of blowdown valves is the blowdown percentage. It refers to the ratio of the quantity of blowdown water (Vblowdown) to that of the feedwater (Vfeed) as the formula below shows.

Types of blowdown valves

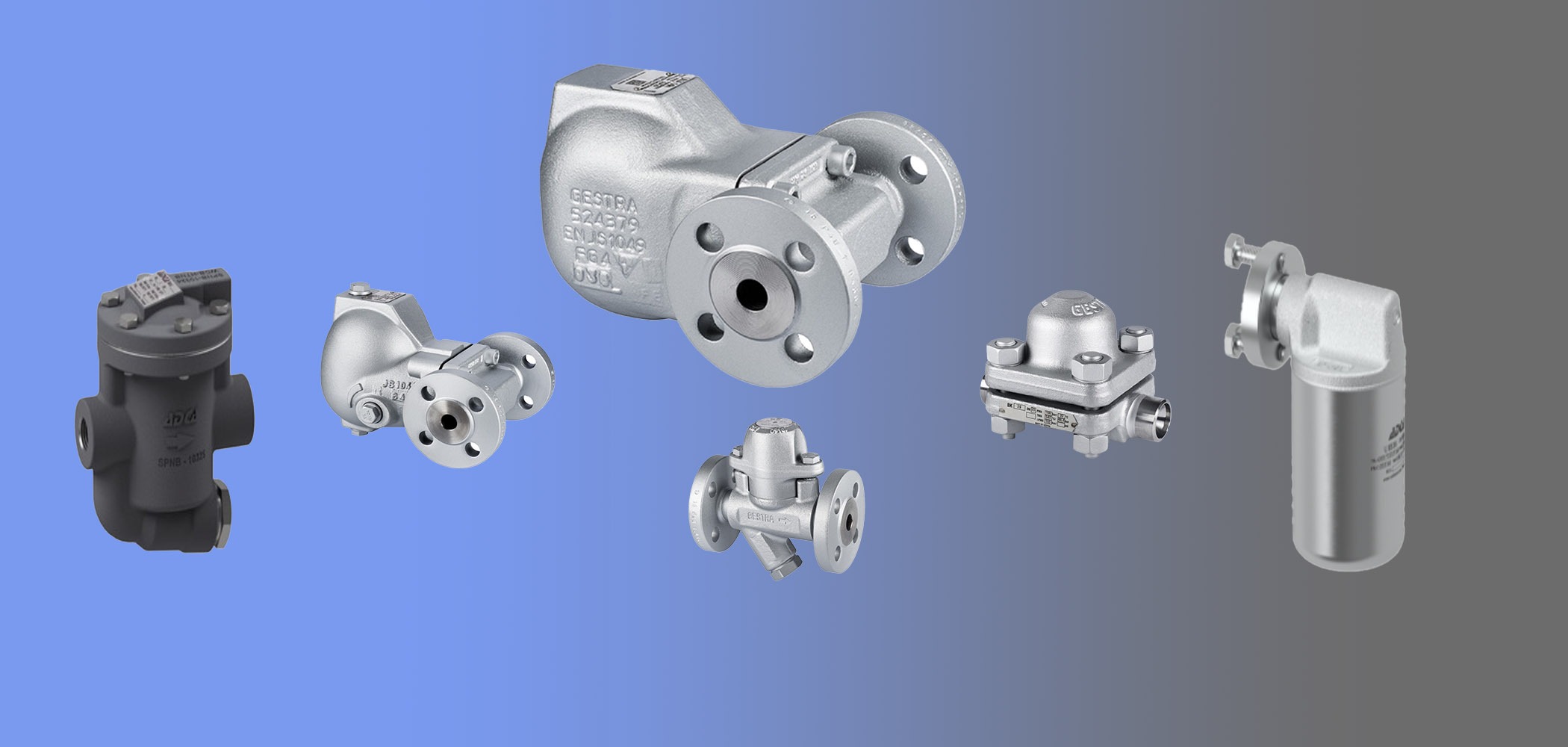

The classification of blowdown valves depends on either the valve location or working interval. Generally, blowdown valves are installed at the surface or the bottom of the equipment, depending on the speed of solid impurities precipitation. Also, the valve may operate continuously or intermittently. Usually, surface blowdown valves operate in steady state, while bottom blowdown valves work intermittently.

Continuous Blowdown Valve

This is suitable for applications where the rate of solid impurities precipitation is relatively slower. For a simple design of this type of valve, a pipe inserts near the surface of the water level. Then, water, along with impurities, goes through the pipe continuously as the valve is normally in the open position.

On the other hand, a more sophisticated design uses a swivel joint with a short length of pipe suspended on a float. Thus, it removes oil floating on the water surface. Typically, surface blowdown valves find use in equipment where a significant amount of vaporization exists. This is because as vaporization occurs, the contaminants, precipitate and remain on the water surface. Also, the outlet of these valves often feeds into a flash tank and provides heating for heat exchangers.

Intermittent Blowdown Valve

As the name implies, this type of blowdown valves installs at the bottom of the equipment. They are opened periodically to enable the evacuation of accumulated solid impurities and sludge. Unlike the surface blowdown valve, this type does not operate in a steady state. This is because prolonged opening decreases the water level quickly, thereby risking a shutdown of the equipment. A basic requirement of this valve is to provide tight shut-off even after repetitive blowdown operations. Also, the drainpipe diameter should be large enough so that the slug does not clog and block the flow.