- Home

- Valsteam ADCA

- Steam Traps-ADCA

- Carbon Steel

Carbon Steel Float Traps

Choose Your Carbon Steel Trap Model

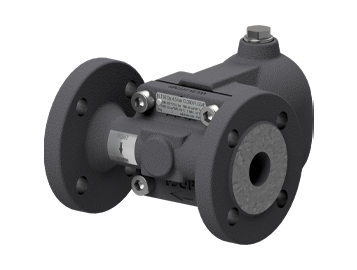

FLT30

The FLT30 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

MATERIAL

Carbon steel

SIZES

1/2” to 1”; DN 15 to DN 25

CONNECTIONS

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

Socket weld (SW) ASME 16.11

MAX. OPERATING PRESSURE

32 bar

MAX. OPERATING TEMPERATURE

250 ºC

FLOW RATE CAPACITY

Up to 595 kg/h

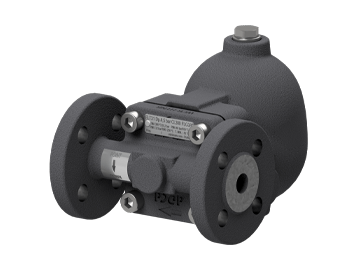

FLT31

The FLT31 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer. Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

MATERIAL

Carbon steel

SIZES

1/2” to 1”; DN 15 to DN 25

CONNECTIONS

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

Socket weld (SW) ASME 16.11

MAX. OPERATING PRESSURE

32 bar

MAX. OPERATING TEMPERATURE

250 ºC

FLOW RATE CAPACITY

Up to 710 kg/h

FLT35

The FLT35 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer. Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

MATERIAL

Carbon steel

SIZES

1”; DN 25

CONNECTIONS

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

Socket weld (SW) ASME 16.11

MAX. OPERATING PRESSURE

32 bar

MAX. OPERATING TEMPERATURE

250 ºC

FLOW RATE CAPACITY

Up to 2490 kg/h

FLT39

The FLT39 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer. Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

MATERIAL

Carbon steel

SIZES

2” ; DN 50

CONNECTIONS

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

Socket weld ASME B16.11

MAX. OPERATING PRESSURE

32 bar

MAX. OPERATING TEMPERATURE

250 ºC

FLOW RATE CAPACITY

Up to 22500 kg/h